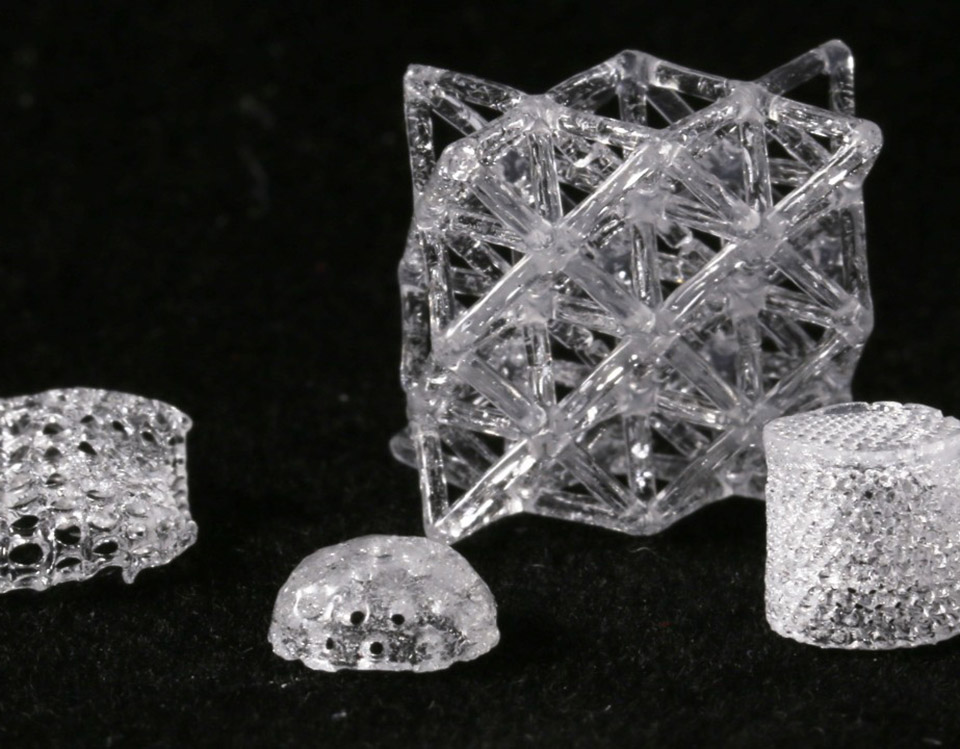

It’s not a simple task to produce glass objects using 3D printing technologies, as just a few groups of researchers around the world have attempted this feat using additive methods. There have been objects made by printing molten glass, but one disadvantage is that this requires extremely high temperatures and heat-resistant equipment. Other methods include powdered ceramic particles that can be printed at room temperature and then sintered later to create glass, but the resulting sculptures are not complex to say the least. ETH Zurich researchers have devised a method to change all of this.

This new method is based on stereo-lithography, or to be more specific, one of the first 3D printing techniques developed during the 1980s. David Moore, Lorenzo Barbera, and Kunal Masania in the Complex Materials group led by ETH processor André Studart have invented a special resin that contains a plastic, along with organic molecules to which glass precursors are bonded. This resin can then be processed using commercially available Digital Light Processing technology, which means an object can thus be built up layer by layer.

- AUTO BED LEVELING: Eliminate the hassles of bed leveling with screws and springs. The built-in inductive sensor can automatically level the print bed, saving you times and aggravation. let makes the print bed absolutely level, ensuring that the first print layers is properly adhere to the build plate. Additionally, each printer is pre-levelled at factory before it ships.

- HEATED AND REMOVABLE GLASS BUILD PLATE: The glass build plate provides the flattest surface possible, ensuring that the first print layers are flawless. The build plate can be heated to 100C, which helps first layer adhesion with materials such as ASA and ABS.

- FILAMENT DETECTOR: With the Ultimate 2, you have no need to worry about running out of filament in the middle of a print. The built-in filament sensor detects when the filament has been consumed and automatically pauses the print, allowing you to load a fresh spool of filament to finish your print. Maximum Power Consumption is 200 watts

We discovered that by accident, but we can use this to directly influence the pore size of the printed object,” said Masania.