Israel-based Aleph Farms and its research partner at the Faculty of Biomedical Engineering at the Technion – Israel Institute of Technology have created the world’s first 3D-printed rib eye steak. The team used a special three-dimensional (3D) bioprinting technology and natural building blocks of meat, which are essentially real cow cells, without genetic engineering and immortalization. This 3D bioprinting technology actually prints living cells that are then incubated to grow, differentiate, and interact, in order to acquire the texture and qualities of a real meat.

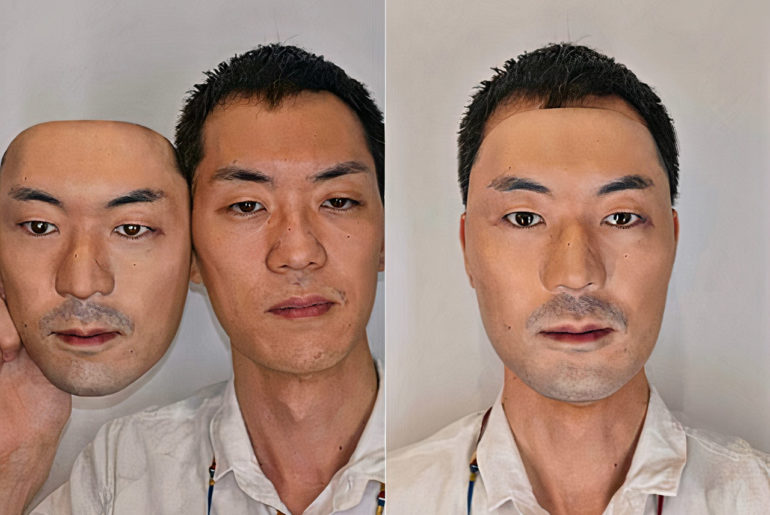

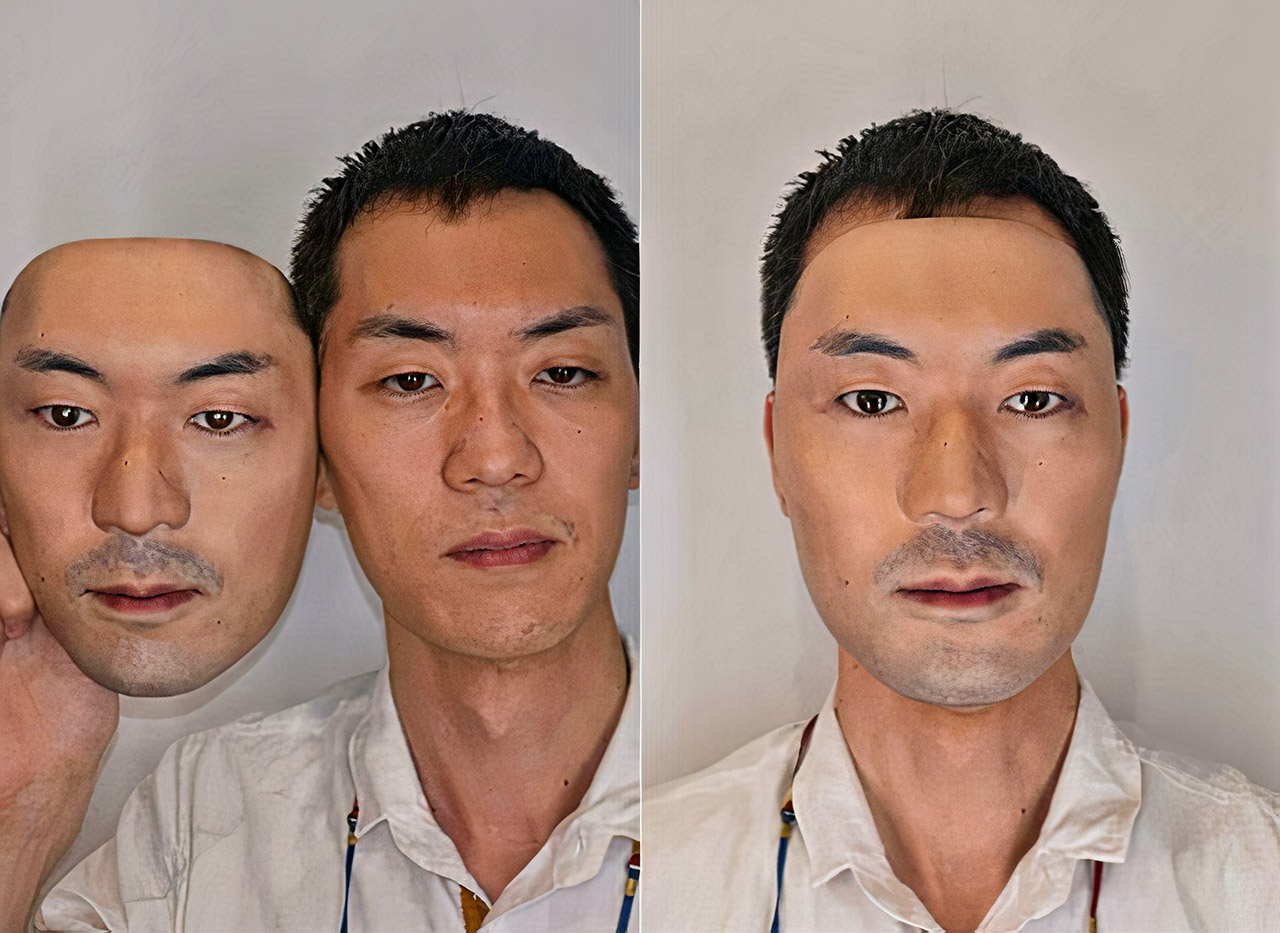

Tokyo-based company Kamenya Omoto specializes in masks, and their latest offering is quite creepy to say the least. The store is offering to pay $340 USD to the rights to your face. Should you accept, they’ll use it to 3D print a hyper-realistic mask, which will then be sold for $940 USD. If customers frequently purchase your mask, the store will then offer to pay a percentage of the sales. The project is officially called “That Face” and has already proven to be a hit.

BRABUS has entered the luxury armored vehicle business with its new INVICTO brand. They are offering the Mercedes-Benz G63 in three different accessory lines: Pure, Luxury and Mission. These models all boast “Invicto Shelter Cell,” which meets OEM factory armoring standards consisting of hot formed armoring steel plates as well as 3D-printed parts.

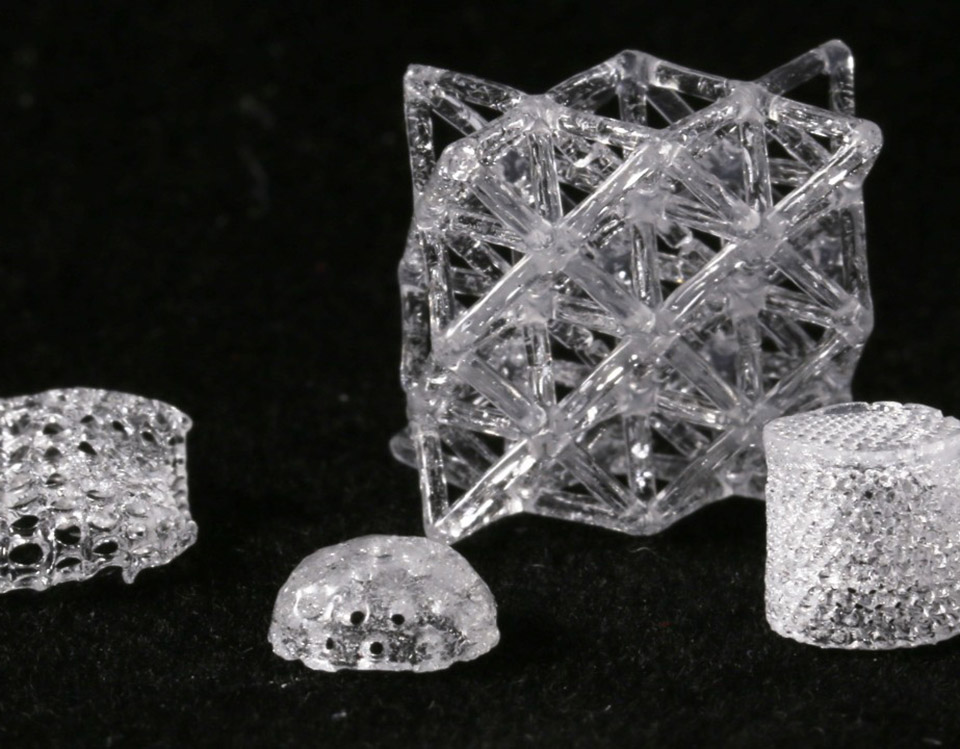

It’s not a simple task to produce glass objects using 3D printing technologies, as just a few groups of researchers around the world have attempted this feat using additive methods. There have been objects made by printing molten glass, but one disadvantage is that this requires extremely high temperatures and heat-resistant equipment. Other methods include powdered ceramic particles that can be printed at room temperature and then sintered later to create glass, but the resulting sculptures are not complex to say the least. ETH Zurich researchers have devised a method to change all of this.

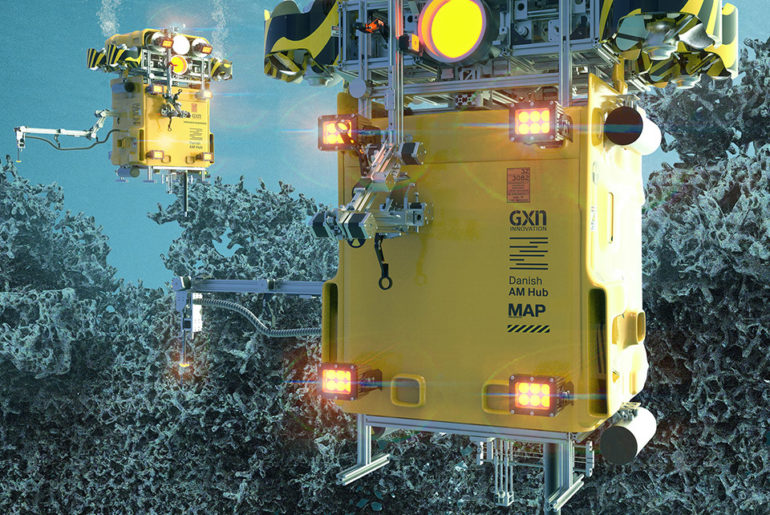

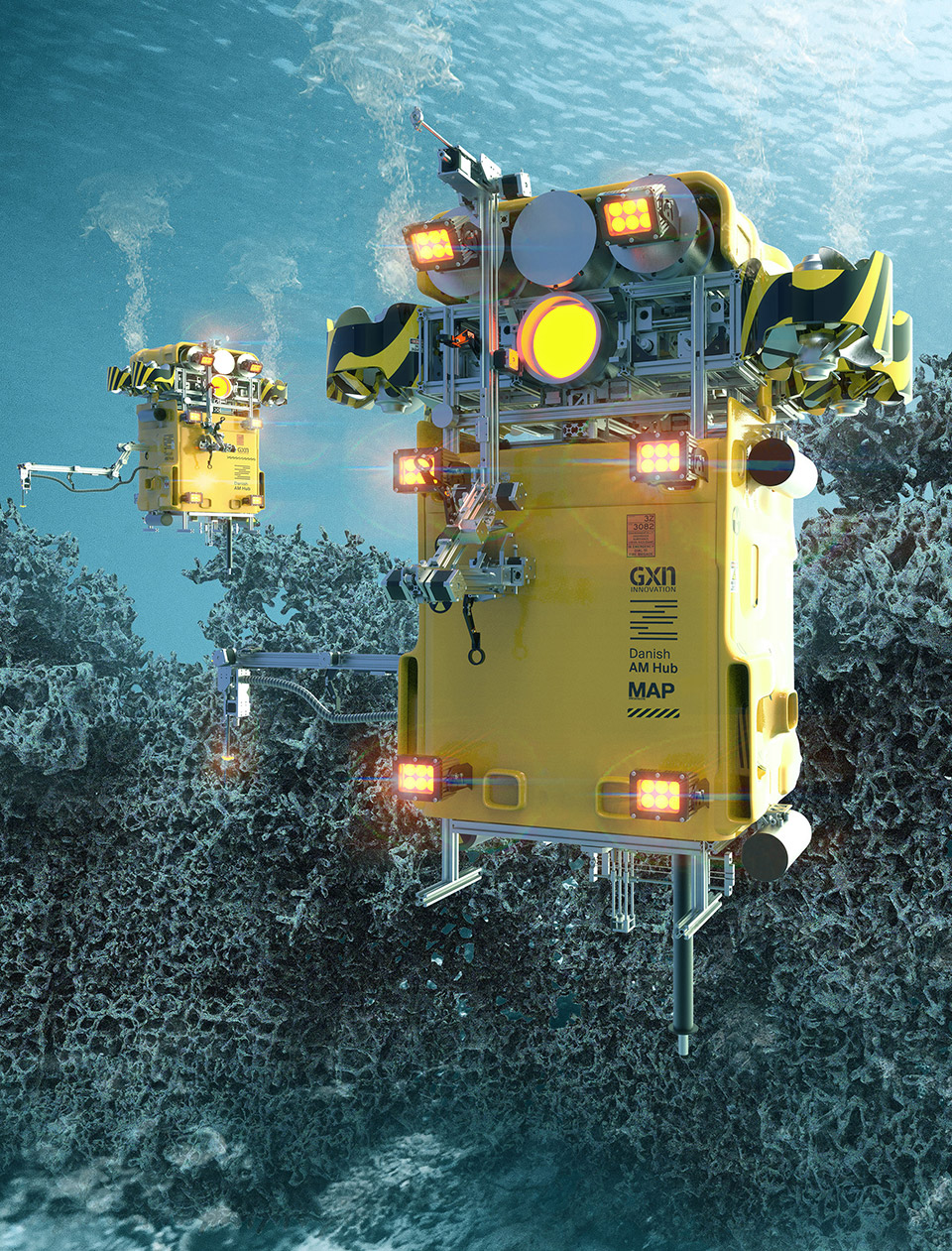

Photo credit: GXN

GXN Innovation has partnered with Dansk AM Hub and MAP Architects to start a “Break the Grid” initiative for construction technologies. In addition to addressing environmental issues, like climate change, the team hopes to one day create 3D-printed robots that can crawl, swim and fly, to repair things in the environment wherever they’re needed. The robot you see above is designed to create artificial reefs by extruding a mixture of sand, glue, and a binder, all extracted from the ocean.